Everything you need to know about the technology and installation

- 4+1 different models

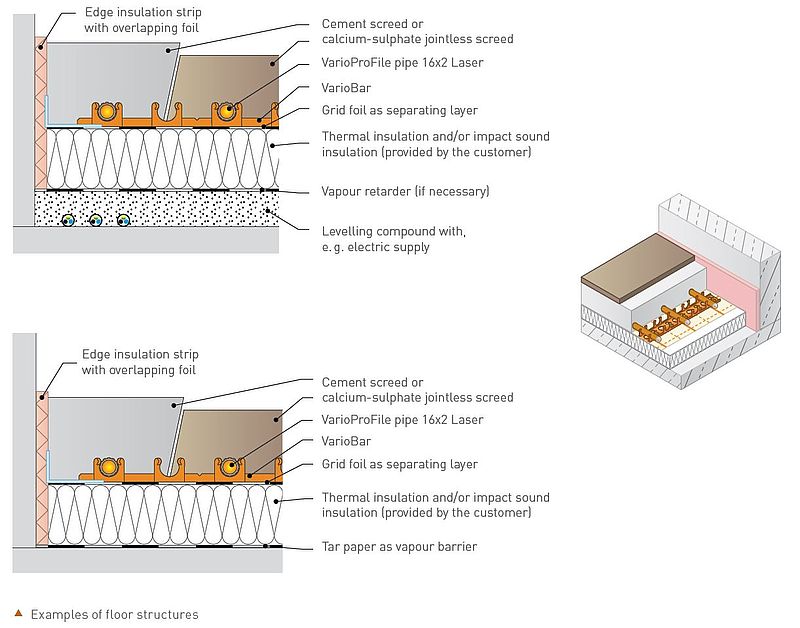

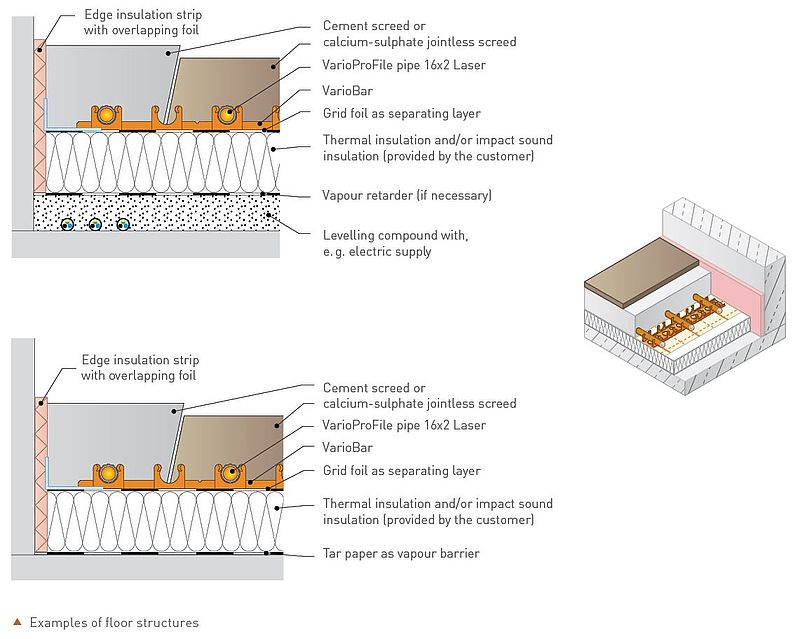

- This is how VarioClip floor heating is constructed

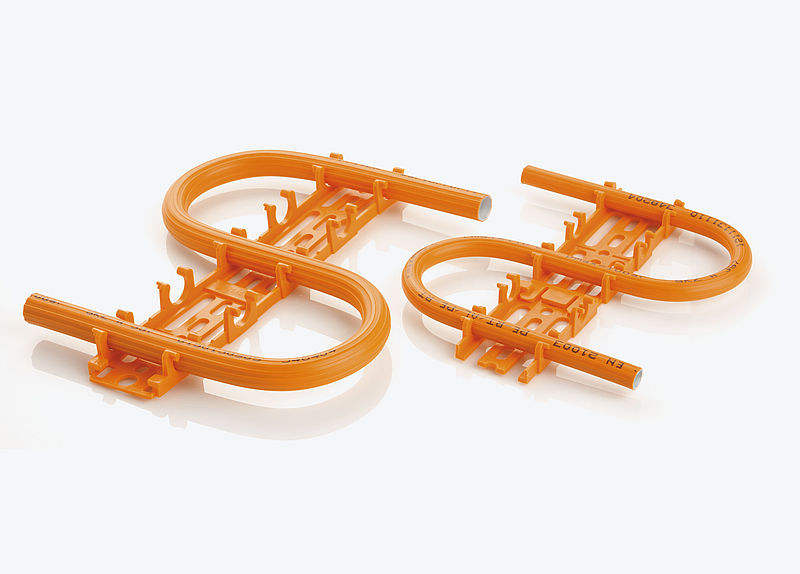

- This is how VarioRast floor heating is constructed

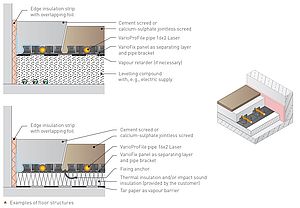

- This is how VarioFix floor heating is constructed

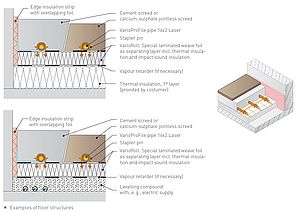

- This is how VarioRoll floor heating is constructed

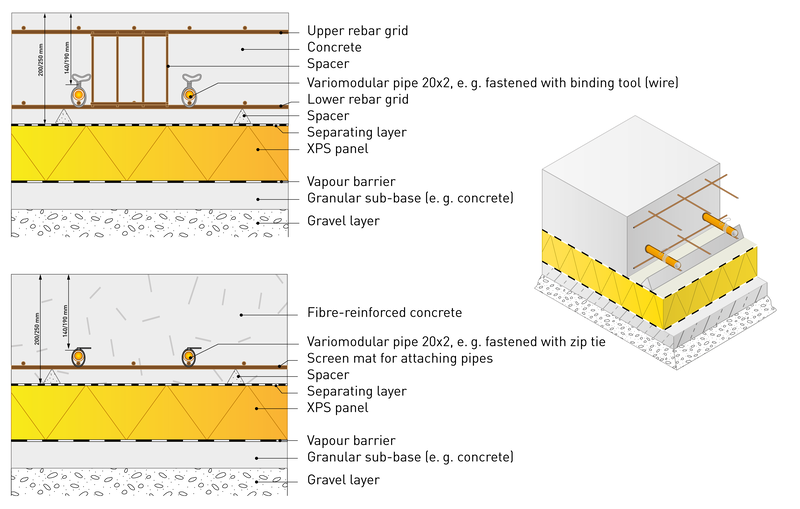

- This is how VarioSolid floor heating is constructed for the industrial sector

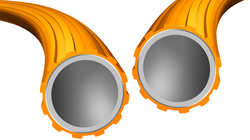

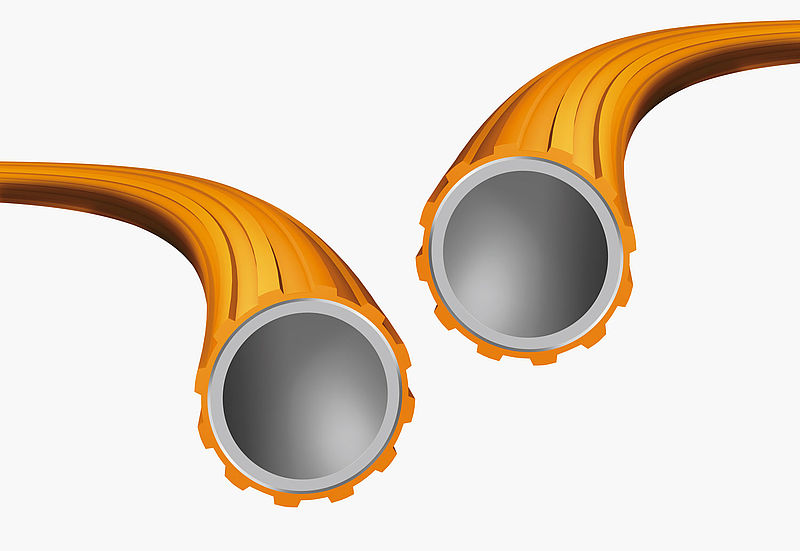

- VarioProFile-pipe 16x2 plus+ – aluminium multi-layer composite pipe

- Piping

- Suitable floor covering

- Residual moisture

- Simple and quick to install

4+1 different models

Floor heating can be installed in screed floors in five different ways:

- VarioClip: Attach the VarioProFile pipe to the wire grid using fixing clips

- VarioRast: Attach the VarioProFile pipe using the VarioBars and grid film on customer-provided thermal insulation

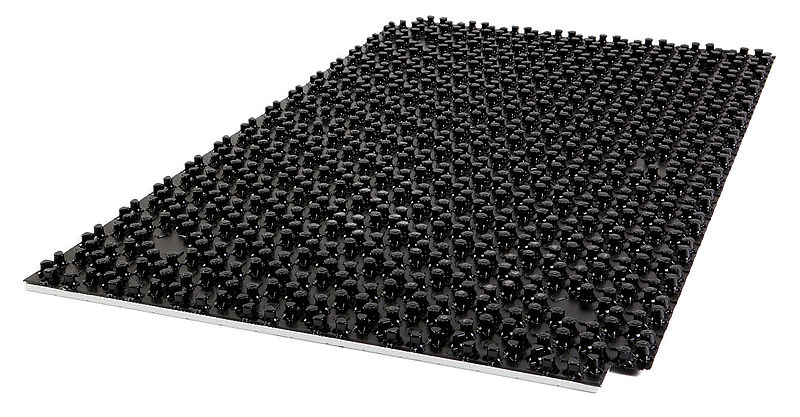

- VarioFix: VarioFix panel with snap fastening system as separating layer and pipe bracket. Mounted on customer-provided insulation

- VarioRoll: Attach the VarioProFile pipe to the VarioRoll thermal and impact sound insulation using stapler pins

- VarioSolid: Floor heating for industrial areas

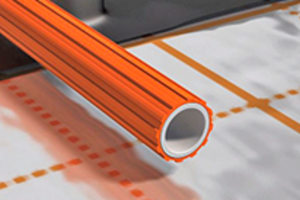

VarioProFile-pipe 16x2 plus+ – aluminium multi-layer composite pipe

The aluminium multi-layer composite pipe 16x2 has a surface structure that is up to 15% larger than that of conventional pipes. A larger surface area means optimised heat transfer. Five layers are joined together and utilise the advantages of both aluminium and plastic.

The inner surface is smooth as glass, making it impossible for deposits to form. The water flows through the pipe without resistance and with minimal pressure losses.

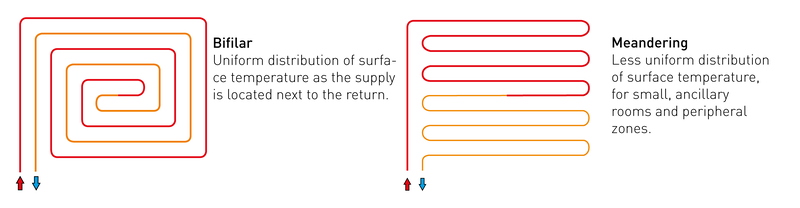

Piping

In the case of Variotherm floor heating systems for screed, the VarioProFile pipe 16x2 plus+ is always located directly in the screed itself. The required thermal output for the individual room determines the spacing between the pipes. 100, 150 and 200 mm spacings are recommended for living spaces – this keeps the rooms comfortable. For rooms such as halls or laboratories, pipes can be laid with up to 300 mm spacings.

200, 250, 300, 350 and 400 mm pipe spacings are used for industrial areas (VarioSolid).

Maximum pipe length per heating circuit including supply pipes: 120 m

Suitable floor covering

All floor coverings suitable for floor heating systems may be used on top of screed floor heating systems. Variotherm recommends a cover with a maximum thermal resistance of 0.1 m²K/W.

In general, the thicker the covering, the slower the heat transfer, since the floor has to be heated up for longer. For example, tiles and natural stone have a high thermal conductivity and quickly radiate heat into the room.

The evenness of the screed must correspond to ÖNORM DIN 18 202.

Residual moisture

The residual moisture of the screed is determined using CM measurements before the floor covering is laid. Regardless of the floor covering, the following values must not be exceeded:

- Calcium sulphate jointless screed: 0.3 %

- Cement screed: 1.8 %

- Jointless cement screed: 1.8 %

Where measurements are below these values, dry heating should be applied, for example in accordance with the BVF (German Federal Association of Surface Heating and Surface Cooling).

Simple and quick to install

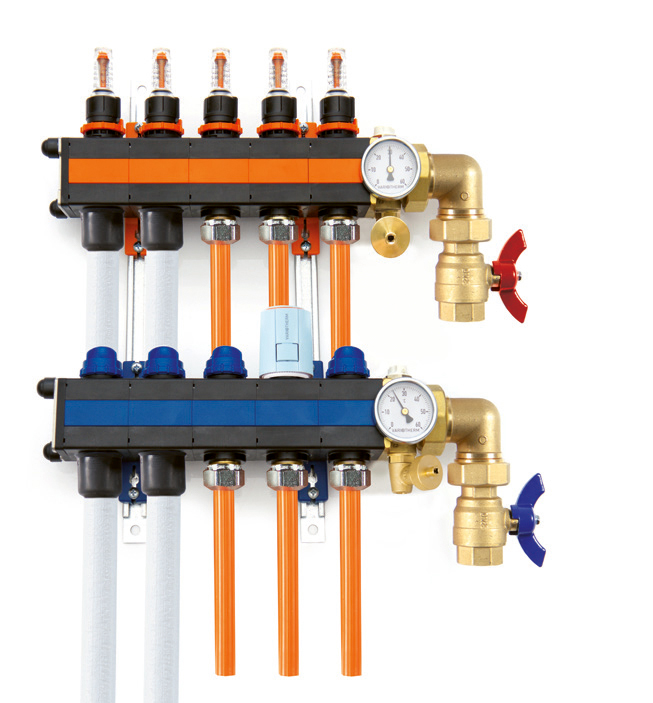

There are four different pipe fixing systems for floor heating for screed floors: the VarioBar, the VarioFix panel, the VarioClips and the stapler pins.

The self-adhesive edge insulation strips are attached along the walls, columns, steps, door frames, etc. The selected fixing system is laid on the prepared subsurface. Then, the system is connected to the heating manifold. Now the floor heating system is filled with water, flushed, deaerated and checked for impermeability. Then, the screed can be applied.